Typical Usages of Refrapure Balls

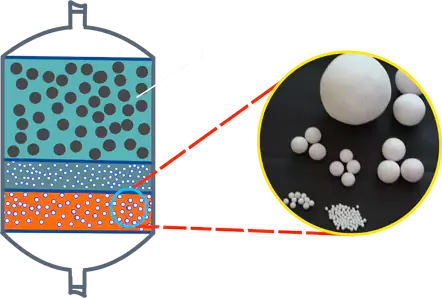

Petrochemical Plants

In petrochemical plants such as oxidation, larger catalysts- 6mm (1/4") dia to 19mm (3/4")- are used.

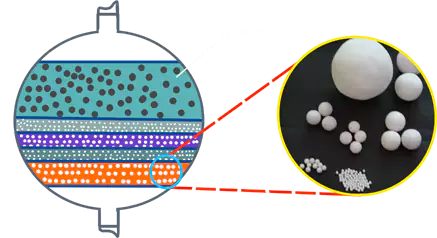

Hydrocracker Units

In applications such as hydrocracker where a typical petroleum process uses high alumina balls of various sizes from 6mm (1/4") to 19mm (3/4").

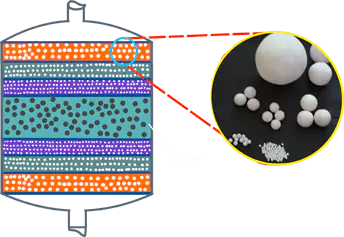

Upflow Reactor Units

In upflow reactors where it is necessary to prevent catalyst bed fluidisation, the balls are graded in reverse order on top of the bed. The size of the balls depends upon the size of the catalyst. To provide sufficient weight to prevent fluidisation, at least nine inches of balls should be installed on top of the bed.

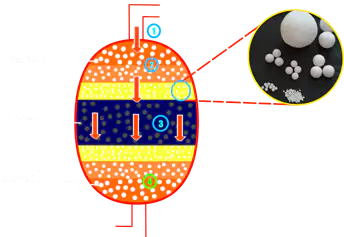

Desiccant Dryer Units

- 1. The raw materials flow down from the upper part,

- 2. The raw materials go through the inert balls, to the catalyst area.

- 3. The chemical reacts at the catalyst area and it gets chemically engineered it become the secondary raw materials/products.

- 4. The chemical engineered Materials/products pass through the inert balls and flows to next process.